Hydrogen energy engineering

- Home

- Hydrogen energy engineering

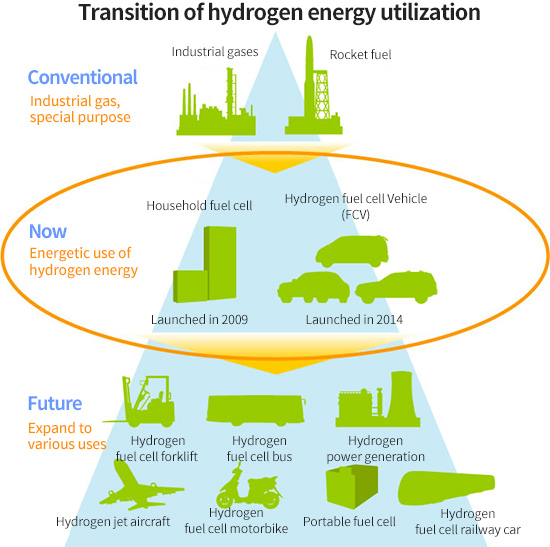

Hydrogen has been mainly used for industrial gas and rocket fuel, but it has attracted attention as a fuel for fuel cell vehicles (FCVs) and household stationary fuel cell systems (ENEFARM) with the development and spread of fuel cells.

Since around 1980, we have been developing fuel cell and hydrogen related products using our own hydrogen combustion technology, heat utilization technology and reaction control technology. In 1983, we developed a hydrogen generator for a 70 kw class phosphoric acid fuel cell and a small afterburner for Enefarm. In fiscal 2013, we will be the first large-scale plant, IS process and continuous hydrogen production test facility. Completed. Based on these technologies and results, we are currently working on the development and demonstration of hydrogen production equipment for hydrogen stations, which is essential for the spread of fuel cell vehicles (FCVs).

Utilization of hydrogen energy

Most of the energy we use is from petroleum, which is easily processed using natural energy such as crude oil, gas and coal, and secondary energy such as city gas and electricity. The most convenient secondary energy is electricity, but electricity has the major disadvantage of being difficult to store. In addition, gasoline and natural gas have problems such as the emission of CO 2 and the depletion of fossil fuels , which cause global warming .

A fuel cell vehicle (FCV) is an electric vehicle (FC) compared to an electric vehicle (EV) driven by electricity generated using natural gas as an energy source and a fuel cell vehicle (FCV) driven by hydrogen obtained by reforming natural gas. Energy efficiency is expected to be about 1.3 times that of EV. With the development of fuel cell technology, hydrogen energy is attracting attention as an alternative to fossil fuel-derived secondary energy.

Hydrogen is the third most abundant element on earth, but in the state of molecular hydrogen there is no place to be produced directly in nature to the extent that it is slightly present. Therefore, hydrogen is manufactured by steam reforming of coal and natural gas and used as industrial materials and rocket fuel, but hydrogen as secondary energy that can be manufactured from various types of energy is attracting attention.

Production of hydrogen energy

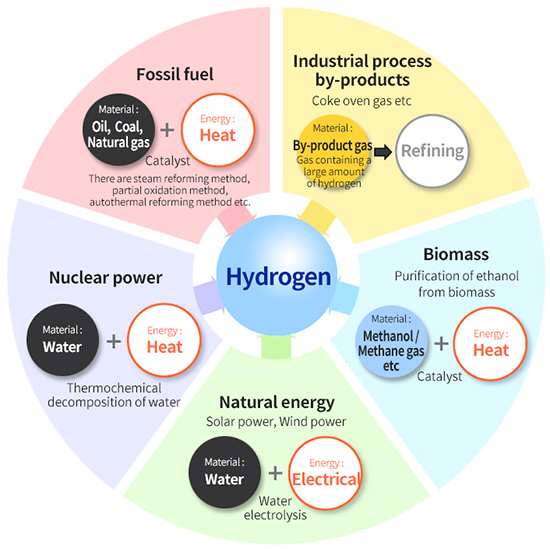

Hydrogen can produce hydrogen by electrolysis of water as well as fossil fuel reforming and by-products of industrial processes, as well as surplus electricity generated from biogas, solar light and wind power. In addition, technology has also been developed to generate hydrogen in large quantities by directly decomposing water from thermochemical reactions using solar heat and nuclear heat. The ability to convert various energy into hydrogen in this way can increase the usage efficiency of all energy. In the future, it is also important to note that by adding a CO2 recovery process to the reforming of fossil fuels, it is possible to create an energy with less impact on the natural environment.

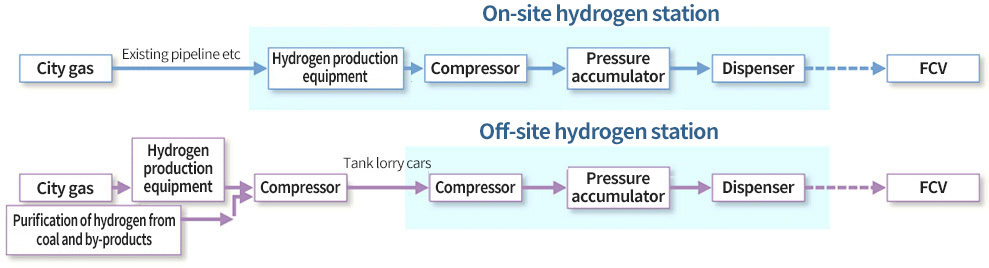

There are two types of hydrogen stations for providing hydrogen to fuel cell vehicles: “On-site stations” and “Off-site stations”. The on-site station is a system that uses the existing city gas pipeline to produce hydrogen in the hydrogen station. As it does not use special tank lorries etc. necessary for high pressure hydrogen transportation, it is possible to cope with the current technology.

On the other hand, the off-site station is a system that uses various energy to produce hydrogen with a large-scale hydrogen generator and carries high-pressure hydrogen to a hydrogen station with a special tank truck. Depending on the environment and space where the hydrogen station is installed, a system will be adopted that takes advantage of the features of each system. Emissions and exhaustion of fossil fuels.

Challenges of hydrogen energy

Hydrogen energy technology, which is expected as a technology to support future energy systems, has shown a brilliant development led by fuel cell technology, but there are issues to be solved for the further spread of hydrogen energy and the realization of a hydrogen society Many are left.

1. Cost reduction of hydrogen

Significant cost reduction is necessary to use hydrogen as energy. At present, the Ministry of Economy, Trade and Industry Resource and Energy Agency’s “Hydrogen / Fuel Cell Strategy Road Map” has a medium- to long-term goal of achieving a 30 yen cost per Nm3. Further cost reductions are considered essential for use in the energy sector. Our company has already succeeded in reducing the cost of hydrogen by dramatically reducing the cost of equipment for hydrogen production by reforming natural gas and other fossil fuels. By lowering the cost of hydrogen production equipment, which is one of the decisive factors for cost reduction of hydrogen, we hope to contribute to the issue of cost reduction of hydrogen.

2. Cost reduction and diffusion of hydrogen stations

According to the country’s hydrogen and fuel cell strategy roadmap, fuel cell vehicles (FCVs) will be introduced to around 40,000 by 2020, around 200,000 by 2025, and around 300,000 by 2030 It has been with. The number of hydrogen stations to support it is 160 by fiscal 2020 and 320 by fiscal 2015, and it is said that the hydrogen station business will be self-sustaining by the late 2020s.

In order to achieve this goal, it is necessary to further reduce the station construction cost. We aim to lower the cost of hydrogen production equipment at the city gas reforming type on-site hydrogen station and optimize the hydrogen generator PSA to simultaneously improve the energy efficiency of the hydrogen station and reduce the construction cost at the same time We have succeeded in developing technology to achieve.

In the future, we will develop our technology to lower the cost of on-site stations that use LPG as a raw material, and contribute to the cost reduction of petroleum-based fuel reformer-type on-site hydrogen stations.

3. Development of new hydrogen utilization technology

Hydrogen fuel power generation technology is expected as a hydrogen application field. Hydrogen-fueled power generation technologies range from air-fired turbine power generation technology fueled by natural gas / hydrogen mixed gas to hydrogen / oxygen combustion turbine technology for electric power business, which are being developed mainly as industrial cogeneration equipment. There is a specification. We will contribute to the development and practical use of new hydrogen power generation technology in terms of development, design, manufacture and evaluation of hydrogen burners that are the basis of power generation technology based on accumulated technology related to hydrogen combustion.

Also for power-to-gas (P2G) systems that are currently attracting global attention as a new application field of hydrogen, system analysis of water electrolysis system, system design and efficiency analysis of the entire P2G system We want to contribute to the practical application of P2G technology from various aspects such as.

4. Build a hydrogen supply chain

Efforts are being made to disseminate FCVs and stationary fuel cell systems (ENE-FARM) with the aim of realizing a hydrogen society. In addition to hydrogen supply to these fuel cell related applications, when considering practical use of hydrogen fuel power generation in the future, it is possible to supply fuel hydrogen at low cost, stably and in large quantities (CO2 The establishment of a free hydrogen supply chain is an important issue. At present, empirical research such as CO2 free hydrogen supply chain using Australian lignite is being carried out on a private enterprise basis, CO 2 free hydrogen supply chain concept using Argentine Patagonia wind resource , or domestic wind resource Various efforts have been developed such as the concept of a CO2 -free hydrogen supply chain utilizing In order to support such research and development efforts aimed at establishing a hydrogen supply infrastructure, we hope that we will make full use of our technology potential.

5. Hydrogen safety technology, regulatory review, deregulation

In order to use hydrogen safely, it is essential to enhance safety technology related to hydrogen. Combined with the development of hydrogen safety technology (hydrogen safety technology), it is necessary to review regulations to make hydrogen easy to use and, if necessary, to ease regulations.

Based on our experience in accident analysis of the Fukushima Daiichi Nuclear Power Station due to the Great East Japan Earthquake, we have the knowledge necessary for the design and production of facilities and equipment that are regulated by laws and regulations. We will actively propose the design and production of equipment based on the hydrogen regulations.

Our company has already succeeded in reducing the cost of hydrogen by dramatically reducing the cost of equipment for hydrogen production by reforming natural gas and other fossil fuels. By lowering the cost of hydrogen production equipment, which is one of the decisive factors for cost reduction of hydrogen, we hope to contribute to the issue of cost reduction of hydrogen.

Our approach to hydrogen energy, examples

Fuel cell, hydrogen

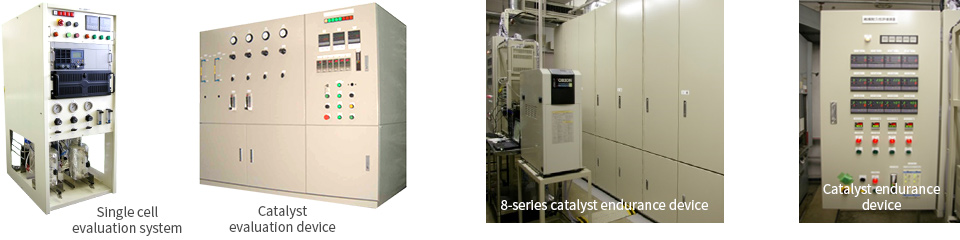

Fuel cell evaluation system, catalyst evaluation system, endurance system

We supply a 100 kw class fuel cell evaluation system to an automobile company. In addition, we supply a large number of specialized fuel cell evaluation devices, catalyst evaluation devices, and endurance devices that are difficult for other companies to deal technically with automobile companies, oil companies, gas company laboratories, universities, etc.

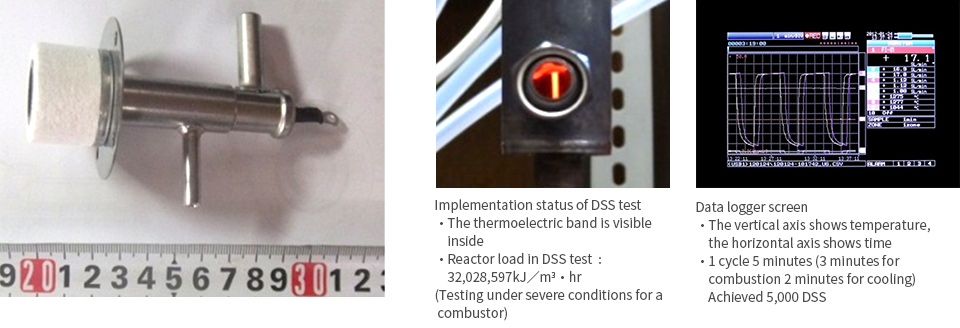

Ultra-compact, high-performance combustor

We are developing ultra-compact, high-performance combustors as reformer combustors installed in Enefarm.

Other

Hydrogen station cost reduction

At present, for on-site hydrogen station hydrogen production equipment, development is under way to reduce the cost of the equipment to 50 million yen or less in order to spread FCV scheduled from fiscal 2015. However, in the conventional hydrogen production apparatus, it is considered that further technical development is necessary to achieve the price target because of the large number of instruments constituting the apparatus.

In fiscal 2013, in fiscal 2013 NEDO (National Research and Development Corporation New Energy and Industrial Technology Development Organization) [R & D on hydrogen technology and development of low-cost equipment and systems for fuel cell vehicles and hydrogen stations] Development of low-cost hydrogen production equipment), and by installing a combined reformer that integrates [Steam Reformer], [CO Converter], and [Steam Generator] into the hydrogen production equipment , We have developed a small-sized, low-cost hydrogen production system that reduces the number of devices that make up the hydrogen production system to less than half that of the conventional hydrogen production system, and has developed it for the purpose of contributing to the spread of FCV.

Target cost of hydrogen production equipment: Achieve 50 million yen or less. (100 Nm3 / h)