Performance

- Home

- Performance

Achievements / Cases

Ammonia synthesis plant manufacturing

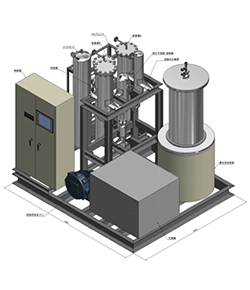

We delivered a demonstration test device equipped with a catalyst that was developed to synthesize renewable energy from renewable energy using renewable energy and that can maintain higher activity at lower temperatures and lower pressures.

[Overview of the ammonia synthesis plant]

Source: National Institute of Advanced Industrial Science and Technology (AIST) Development of a catalyst for synthesizing ammonia at low temperature and low pressure

Hydrogen energy engineering

[Overview of hydrogen production equipment equipped with combined reformers]

Source: (National Research and Development Corporation) New Energy and Industrial Technology Development Organization (NEDO) Development of low-cost hydrogen production equipment for on-site hydrogen stations

On-site hydrogen stations do not transport hydrogen, but hydrogen is generated in the stations. In this project, the hydrogen production equipment was made compact (combined reformer) to reduce costs.

[Overview of the combined reformer]

Source: (National Research and Development Corporation) New Energy and Industrial Technology Development Organization (NEDO) Development of low-cost hydrogen production equipment for on-site hydrogen stations

[Overall view of hydrogen production equipment equipped with a combined reformer]

[Control panel and gas chromatography]

Source: (National Research and Development Corporation) New Energy and Industrial Technology Development Organization (NEDO) Development of low-cost hydrogen production equipment for on-site hydrogen station

Mechanical and chemical plant design and manufacture

We delivered a continuous hydrogen production test facility using the IS process that decomposes water by thermal energy and generates hydrogen and oxygen using chemical reactions using sulfuric acid and hydrogen iodide.

[Continuous hydrogen production test equipment]

Source: (National Research and Development Corporation) Japan Atomic Energy Agency

Press release

Demonstration project in Noshiro using hydrogen mixed gas as fuel for household gas appliances(June 11, 2019)

A demonstration project for expanding the use of hydrogen has begun at a plant installed on the site of the wind power company “Kaze no Matsubara Natural Energy” in Noshiro City, Akita Prefecture. Using electricity generated at the company’s wind farm nearby, it breaks down the water and produces hydrogen. Make a gas mixture similar to city gas and verify how safe it can be used as fuel for household gas appliances.

Awards history

The 24th “Small and Medium Business Excellent New Technology / New Product Award”

[Excellent Award] The inspection technology by electromagnetic induction

The “24th Small and Medium Business Excellent New Technology / New Product Award” held in April 2012 received the “Excellent Award” among the 441 entries.

Recent achievements

Equipment design and production

- Nuclear power plant (in-core inspection and repair equipment design and production)

- Thermal power plant (parts design and production for replacement)

- Equipment for hydrogen production (design and manufacture of sulfuric acid decomposition element test equipment)

- Aircraft inspection system (High-speed automatic nondestructive inspection system design and production)

- Nuclear fuel reprocessing facility (automatic handling system design)

- Nuclear fuel reprocessing facility Thermal power plant (Various high-performance domesticated equipment design and production / New-type nondestructive inspection device basic development / Intake port cleaning device design and production)

Technical evaluation and support

- Nuclear power plant (Aging assessment creation support)

- Nuclear power plant (Aging standard international standard creation support)

- Nuclear power plant Thermal power plant (Waste treatment technology confirmation test equipment / design, manufacture, test, evaluation / Evaluation of parts domesticizing technology for replacement parts)

Analysis and support

- Nuclear power plant (in-reactor structural stress analysis)

- Nuclear power plant (pressure vessel stress analysis)

- Nuclear power plant (turbine parts stress analysis)

- Nuclear fuel reprocessing facility (in-plant equipment stress analysis)

- Nuclear fuel reprocessing facility (pipe vibration analysis)

- Nuclear power plant (flow analysis in heat exchangers and pipes)

- Commercial facility (frame structure analysis)

- Aerospace Equipment (Dynamic Response Analysis)

Main customer

- Japan Atomic Energy Agency

- New Energy and Industrial Technology Development Organization

- National Institute of Advanced Industrial Science and Technology

- The Institute of Applied Energy

- TOHOKU UNIVERSITY

- UNIVERSITY OF YAMANASHI

- Tokyo Electric Power Company

- Tokyo Electric Power Services CO.,Ltd.

- Nuclear Engineering and Services Company

- Tokyo Power Technology

- TEPCO SYSTEMS CORPORATION

- TOKYO ENERGY & SYSTEMS INC.

- Nuclear Fuel Industries,Ltd.

- Tokyo Nuclear Services Co., Ltd.

- ATOX Co., Ltd.

- JGC CORPORATION

- SHIMIZU CORPORATION

- KANTO YAKIN KOGYO CO.,LTD.

- MUTSUBISHI RUBBER CO., LTD.

- PARSYSTEM

- JNFL Japan Nuclear Fuel Limited.

- J_TECH Inc.

- THE CHUGOKU ELECTRIC POWER CO.,INC.

- Hitachi-GE Nuclear Energy, Ltd.

- TOSHIBA CORPORATION

- Fuji Electric Co., Ltd.

- NEC Corporation

- IHI AEROSPACE ENGINEERING CO., LTD.

- TOSHIBA ELECTRONICS ENGINEERING CORPORATION

- NTT DATA INSTITUTE OF MANAGEMENT CONSULTING, Inc.

- KOBE STEEL, LTD.

- Honda Motor Co., Ltd.

- Shin Nippon Chemical Consultant, Ltd.

- Intergraph Corporation

* Regarding the name abbreviation, random order

Cooperation company

- Comtec Quest & Company

- PAR SYSTEMS

- Flow Science Japan

- Research Center of Computational Mechanics, Inc.